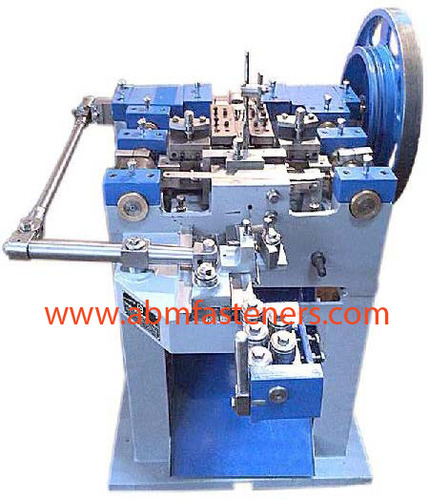

Automatic High Speed Nail Making Machine

Product Details:

- Product Type Other

- Technology Other

- Power Source Electricity

- Operating Type Automatic

- Power 1-10 Horsepower (HP)

- Surface Treatment Painted

- Color any color

- Click to View more

X

Automatic High Speed Nail Making Machine Price And Quantity

- 1 Unit

Automatic High Speed Nail Making Machine Product Specifications

- Other

- Industrial

- any color

- Painted

- 1-10 Horsepower (HP)

- Automatic

- Electricity

- 100-550 Pcs/min

- One year Warranty against any manufacturing defects except mishandling / accidental

- Other

Automatic High Speed Nail Making Machine Trade Information

- NEW DELHI

- Letter of Credit at Sight (Sight L/C), Letter of Credit (L/C), Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- 30 Unit Per Month

- 2 Week

- WOODEN CASE PACKING

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- ISO 9001:2015

Product Description

FEATURES CONSTRUCTION ABM TOOLS Panel Pin & Wire Nails making machines crank type are made from high grade castings and steel.Machines ensure perfect sturdy construction and long life. DRIVE Three shafts design has been adopted to ensure efficient smooth working.The main crank is direct operated by motor.The side shafts are driven by four bevel gears, which operate cutting tools.The separate shafts for cutting ensure correct adjustment of tools. BEARING Main crank & side shafts are fitted with special gun metal Bushes to ensure long life.All the Bushes & Lubricating Points are provided with cup type oil reservoirs. WORKING OF MACHINE The wire end from coil passes through straightening rollers and fed intermittently in the gripping dies, which close firmly allowing heading punch to press the head of the nails, then grip loosened and required length of the nail is fed constantly, where it is cut by cutting tools leaving ample stock for the head of the next nail.Thus ready nail is ejected by the ejector.The operations are repeated in each revolution. WIRE FEED The wire feed is obtained from main crank shaft.The desired length of nail is easy to set by adjustment bolt. ACCESSORIES FOR THE PLANT Grinding Machine, Polishing Drum and Spare Dies, etc. SPECIFICATION (Wire Nail / Panel Pin Making Machine) Item Code No. ABM-FM-6570 ABM-FM-6571 ABM-FM-6572 Length of Nail / Panel Pin 1/4" to 1"(6 to 25 mm) 1/2" to 1-1/2"(12 to 38 mm) 1/2" to 2"(12 to 50 mm) Thickness of Wire Gauge 0.9 to 1.4 mm(20 to 17 SWG) 1.2 to 2 mm(18 to 14 SWG) 1.6 to 2.6 mm(16 to 12 SWG) Production Per Minute 500 to 550 Pcs. 400 to 450 Pcs. 300 to 350 Pcs. Motor Required 1 H.P. x 1400 R.P.M. 1.5 H.P. x 1440 R.P.M. 2 H.P. x 1440 R.P.M. Net Weight of Machine 225 Kg. 350 Kg. 500 Kg. Gross Weight of Machine 300 Kg. 450 Kg. 650 Kg. Case Size 33" x 29" x 32" 33" x 32" x 35" 36" x 37" x 37" SPECIFICATION (Wire Nail Making Machine) Item Code No. ABM-FM-6573 ABM-FM-6574 ABM-FM-6575 ABM-FM-6576 Length of Nail 3/4" to 3"(20 to 75 mm) 1" to 4"(25 to 100 mm) 2" to 6"(50 to 150 mm) 2" to 8"(50 to 200 mm) Thickness of Wire Gauge 2 to 3.7 mm(14 to 9 SWG) 2.6 to 4 mm(12 to 8 SWG) 4 to 6 mm(8 to 4 SWG) 4 to 7 mm(8 to 2 SWG) Production Per Minute 225 to 275 Pcs. 175 to 210 Pcs. 100 to 125 Pcs. 90 to 100 Pcs. Motor Required 3 H.P. x 1400 R.P.M. 5 H.P. x 1400 R.P.M. 7.5 H.P. x 960 R.P.M. 10 H.P. x 960 R.P.M. Net Weight of Machine 850 Kg. 1200 Kg. 1800 Kg. 2400 Kg. Gross Weight of Machine 1050 Kg. 1550 Kg. 2400 Kg. 3200 Kg. Case Size 47" x 56" x 42" 52" x 51" x 44" 65" x 72" x 49" 84" x 77" x 57"FAQs of Automatic High Speed Nail Making Machine:

Q: What is the production capacity of the Automatic High Speed Nail Making Machine?

A: The production capacity ranges from 100 to 550 pieces per minute.Q: What is the power source for the Automatic High Speed Nail Making Machine?

A: The power source for this machine is electricity.Q: Does the Automatic High Speed Nail Making Machine come with a warranty?

A: Yes, the machine comes with a one-year warranty against any manufacturing defects, excluding mishandling or accidental damage.Q: What is the power requirement of the Automatic High Speed Nail Making Machine?

A: The machine requires power ranging from 1 to 10 horsepower (HP).Q: What is the surface treatment applied to the Automatic High Speed Nail Making Machine?

A: The surface treatment applied to this machine is painted.Q: Can the machine be customized to any color?

A: Yes, the machine can be painted in any color as per customer requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email